直縫專機(jī)可焊接什么以及注意事項(xiàng)

來源:http://maxsenz.com/ 發(fā)布時間:2023-05-11 瀏覽次數(shù):0

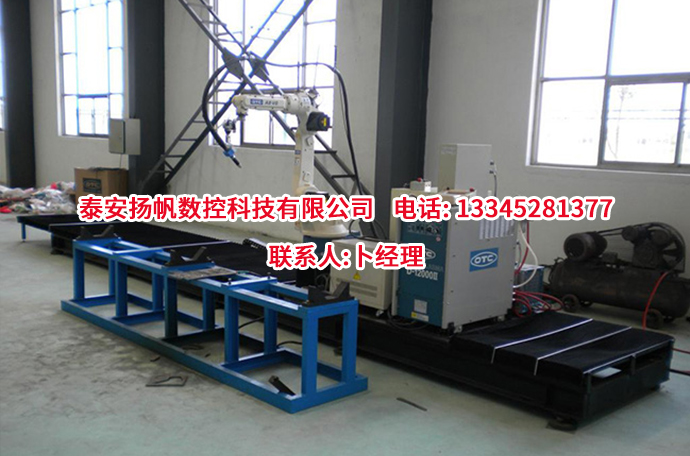

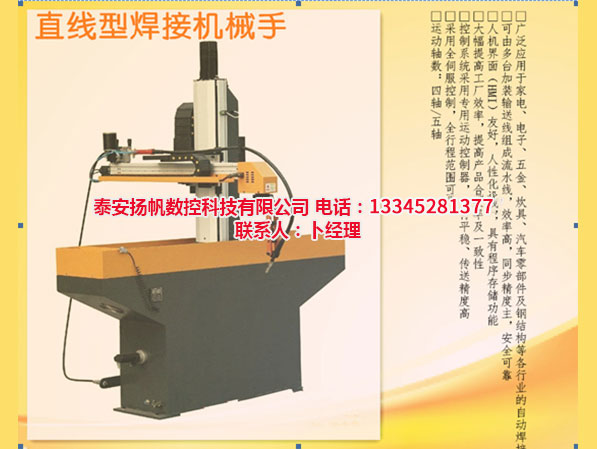

直縫專機(jī)是一種常見的焊接設(shè)備,一般用于焊接直縫管道。該設(shè)備可以用于焊接不同種類的金屬,如普通碳鋼、合金鋼、不銹鋼等材料。不過,不同種類的材料需要使用不同種類的電極和焊接參數(shù),以獲得佳的焊接效果。需要注意的是,直縫專機(jī)在焊接時需要注意以下幾點(diǎn)事項(xiàng):

A straight seam welding machine is a common welding equipment commonly used for welding straight seam pipelines. This equipment can be used for welding different types of metals, such as ordinary carbon steel, alloy steel, stainless steel, and other materials. However, different types of materials require the use of different types of electrodes and welding parameters to achieve optimal welding results. It should be noted that the straight seam special machine needs to pay attention to the following points when welding:

1.預(yù)處理:山東焊接專機(jī)廠家提醒,在進(jìn)行焊接前,必須對待焊接的金屬進(jìn)行預(yù)處理,如清洗、切割、打磨等,以確保焊接部位干凈、平整、無雜質(zhì)。

1. Pre treatment: The Shandong welding machine manufacturer reminds that before welding, the metal to be welded must be pre treated, such as cleaning, cutting, polishing, etc., to ensure that the welding area is clean, flat, and free of impurities.

2.電極選擇:根據(jù)待焊接的金屬類型和規(guī)格,選擇合適的焊接電極,以獲得佳的焊接效果。

2. Electrode selection: Select appropriate welding electrodes based on the type and specifications of the metal to be welded, in order to achieve optimal welding results.

3.焊接參數(shù):根據(jù)焊接材料和金屬厚度等因素,合理調(diào)整焊接電流、電壓、焊接速度等參數(shù),確保焊接質(zhì)量和效率。

3. Welding parameters: Reasonably adjust parameters such as welding current, voltage, and welding speed based on factors such as welding material and metal thickness to ensure welding quality and efficiency.

4.過熱控制:在焊接過程中,控制焊接熱量,避免過熱導(dǎo)致焊接質(zhì)量下降或產(chǎn)生裂紋等問題。

4. Overheat control: During the welding process, control the welding heat to avoid problems such as decreased welding quality or cracks caused by overheating.

5.焊接環(huán)境:在焊接時,要注意保持焊接環(huán)境的干燥、通風(fēng)和清潔,避免產(chǎn)生雜質(zhì)和氧化物,影響焊接質(zhì)量。

5. Welding environment: During welding, attention should be paid to maintaining a dry, ventilated, and clean welding environment to avoid impurities and oxides that may affect the welding quality.

總之,直縫專機(jī)可以焊接不同種類的金屬材料,但需要注意事項(xiàng),如預(yù)處理、電極選擇、焊接參數(shù)、過熱控制和焊接環(huán)境等。只有遵守好這些注意事項(xiàng),才能確保焊接質(zhì)量和效率,延長焊接設(shè)備的使用壽命。更多事項(xiàng)就來我們網(wǎng)站http://maxsenz.com咨詢!

In short, straight seam machines can weld different types of metal materials, but precautions need to be taken, such as pre-treatment, electrode selection, welding parameters, overheating control, and welding environment. Only by following these precautions can welding quality and efficiency be ensured, and the service life of welding equipment be extended. For more information, come to our website http://maxsenz.com consulting service

上一篇:數(shù)控焊接設(shè)備的潤滑油更換依據(jù)指標(biāo)

下一篇:自動化焊接設(shè)備的三大特點(diǎn)