數(shù)控焊接設備維護保養(yǎng)注意這幾點

來源:http://maxsenz.com/ 發(fā)布時間:2023-03-07 瀏覽次數(shù):0

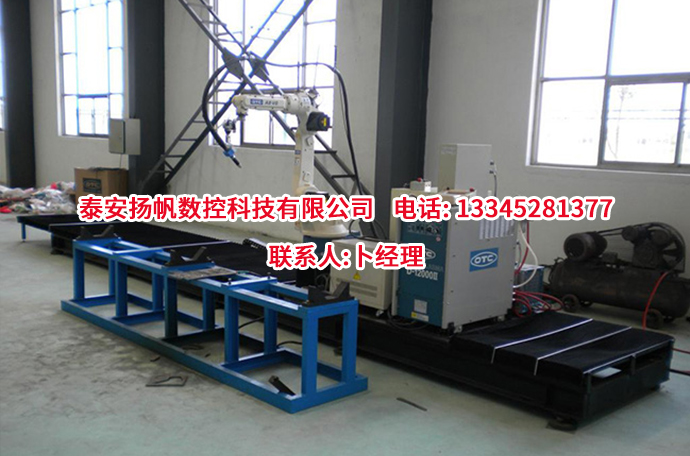

隨著焊接自動化和智能化水平的不斷發(fā)展,越來越多的企業(yè)使用數(shù)控焊接設備來代替?zhèn)鹘y(tǒng)焊機,在生產(chǎn)線中可以提高焊接效率,穩(wěn)定產(chǎn)品質量,數(shù)控焊接設備屬于機械設備,在使用中會出現(xiàn)老化磨損的情況,為了避免因為設備因素導致焊接質量問題,維護保養(yǎng)是重要一步。

With the continuous development of welding automation and intelligent level, more and more enterprises use numerical control welding equipment to replace traditional welding machines, which can improve the welding efficiency and stabilize the product quality in the production line. Numerical control welding equipment is a mechanical equipment, which will appear aging and wear in use. In order to avoid welding quality problems caused by equipment factors, maintenance is an important step.

1、日檢查維護保養(yǎng):在山東數(shù)控焊接設備工作結束之后,需要進行日常檢查維護,檢查送絲機構、氣體流量、保護系統(tǒng)、水循環(huán)系統(tǒng)、焊槍TCP點是否正常,并做好點檢記錄,發(fā)現(xiàn)問題及時修正。

1. Daily inspection and maintenance: after the work of Shandong CNC welding equipment is completed, daily inspection and maintenance shall be carried out to check whether the wire feeding mechanism, gas flow, safety protection system, water circulation system and welding gun TCP point are normal, and the spot check record shall be made, and the problems found shall be corrected in time.

2、周檢查維護保養(yǎng)進行六清理:清理數(shù)控焊接設備各軸以及本體;清理焊機水箱過濾網(wǎng);清理壓縮空氣進出口的過濾網(wǎng);清理送絲機構;清理焊槍內(nèi)的雜質,預防出現(xiàn)焊接缺陷。

2. Weekly inspection and maintenance shall be carried out in six ways: cleaning all shafts and bodies of CNC welding equipment; Clean the filter screen of the welding machine water tank; Clean the filter screen at the inlet and outlet of compressed air; Clean the wire feeding mechanism; Clean the impurities in the welding gun to prevent welding defects.

3、月檢查維護保養(yǎng):對各軸涂抹潤滑油,清理控制柜以及焊機,檢查焊機水箱的水位,及時補充冷卻液,檢查數(shù)控焊接設備的配件,及時更換。

3. Monthly inspection and maintenance: apply lubricating oil to each shaft, clean the control cabinet and welding machine, check the water level of the welding machine water tank, replenish the coolant in time, check the accessories of the numerical control welding equipment, and replace them in time.

數(shù)控焊接設備維護保養(yǎng)注意以下幾點:

Pay attention to the following points in the maintenance of numerical control welding equipment:

1、使用潤滑油注意:在數(shù)控焊接設備本體的注油孔不能加普通黃油,會導致各軸不能靈活轉動,需要加白色的潤滑油。

1. Note for using lubricating oil: ordinary grease cannot be added to the oil filling hole of the NC welding equipment body, which will cause the shaft to be unable to rotate flexibly, and white lubricating oil needs to be added.

2、電纜線保護:數(shù)控焊接設備在工作過程中會對電纜線進行移動和拖拽,電纜線不能進行踩踏、擠壓,在進行拖拽的時候注意避免電纜線纏繞。

2. Cable protection: CNC welding equipment will move and drag the cable during operation. The cable cannot be trampled or squeezed. Pay attention to avoid cable winding during dragging.

3、焊槍保護:在對焊槍進行維護保養(yǎng)的時候,主要注意兩方面,一方面檢查導電嘴是否需要更換,另一方面清理送絲軟管,防止雜質堆積影響正產(chǎn)焊接。

3. Welding torch protection: When maintaining the welding torch, pay attention to two aspects: on the one hand, check whether the electric nozzle needs to be replaced, and on the other hand, clean the wire feeding hose to prevent the accumulation of impurities from affecting the production welding.

4、選用質量好的焊絲:數(shù)控焊接設備采用的是桶裝焊絲,這樣在焊接過程不需要頻繁更換焊絲影響焊接效率,質量好的焊絲可以保證焊接質量的穩(wěn)定性,預防送絲不均等現(xiàn)象。

4. Select welding wire with good quality: barreled welding wire is used in the numerical control welding equipment, so it is not necessary to change the welding wire frequently during the welding process to affect the welding efficiency. The welding wire with good quality can ensure the stability of the welding quality and prevent uneven wire feeding.

5、選擇氣體保護焊:混合氣體保護焊講求混合氣配比準確、混合均勻,二氧化碳氣體需要保證純凈。

5. Select gas shielded welding: mixed gas shielded welding requires accurate mixture ratio and uniform mixing, and carbon dioxide gas needs to be pure.

以上就是數(shù)控焊接設備的維護保養(yǎng)注意事項,維護保養(yǎng)適當?shù)臄?shù)控焊接設備可以提高焊接產(chǎn)品的穩(wěn)定性,有利于延長使用壽命,為企業(yè)提升生產(chǎn)效益。更多相關內(nèi)容就來我們網(wǎng)站http://maxsenz.com咨詢吧!

The above are the precautions for the maintenance of CNC welding equipment. Proper maintenance of CNC welding equipment can improve the stability of welding products, extend the service life and improve the production efficiency for enterprises. Come to our website for more relevant content http://maxsenz.com Ask!