焊接機器人的清槍器你了解多少呢

來源:http://maxsenz.com/ 發(fā)布時間:2021-02-27 瀏覽次數(shù):0

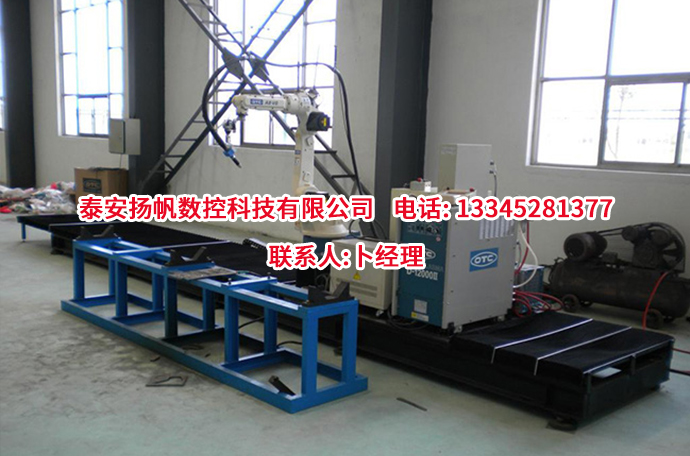

焊接機器人自動化生產(chǎn)需要減少人力,提高產(chǎn)品一致性,提高產(chǎn)品質(zhì)量,更適合大規(guī)模生產(chǎn),降低生產(chǎn)成本,提高生產(chǎn)效率。今天焊接機器人,焊接機器人廠家的小編來為您講講清槍器的用處:

Welding robot automation production needs to reduce manpower, improve product consistency, improve product quality, more suitable for large-scale production, reduce production costs, improve production efficiency. Today's welding robot, a small editor from the welding robot manufacturer, will tell you the use of the gun:

清槍器主要是用作清理機器人自動焊接在工作過程中產(chǎn)生的粘堵在焊槍氣體保護套內(nèi)的飛淺物,確保氣體長期暢通無阻,有效地阻隔空氣進入焊接區(qū),保護焊接溶池提高焊縫質(zhì)量。能清理導電咀上焊煙產(chǎn)生的積塵,疏通清理連接管上保護氣體出氣孔,給保護套噴灑耐高溫防堵濟,降低焊渣對槍套、槍咀的死粘連,增加耐用度。

The gun cleaner is mainly used to clean up the shallow objects stuck in the gas protection sleeve of the welding gun during the automatic welding process of the robot, to ensure that the gas is unobstructed for a long time, effectively block the air into the welding area, protect the welding pool and improve the welding quality. It can clean the dust generated by welding smoke on the conductive nozzle, dredge and clean the protective gas outlet on the connecting pipe, spray the protective sleeve with high temperature resistance and anti blocking, reduce the dead adhesion of welding slag on the gun sleeve and nozzle, and increase the durability.

還能解決人手清理存在的以下問題:(1)減輕生產(chǎn)人員的工作量。(2)避免人工清理不準時而影響焊接質(zhì)量。(3)避免人工清理反復拆裝保護套使保護套和連接管之間的接駁螺紋磨損,延長使用時間,降低成本。(4)避免因螺紋磨損導致氣體保護套安裝歪斜,氣體導偏而造成保護失效。

It can also solve the following problems: (1) reduce the workload of production personnel. (2) Avoid manual cleaning not on time and affect the welding quality. (3) Avoid manual cleaning, repeatedly dismounting the protective sleeve, so that the connecting thread between the protective sleeve and the connecting pipe is worn, prolong the service time and reduce the cost. (4) To avoid the installation deviation of gas protection sleeve due to thread wear and the protection failure caused by gas deviation.

目前國際機器人界都在加大科研力度,進行機器人共性技術(shù)的研究。從機器人技術(shù)發(fā)展趨勢看,焊接機器人和其它工業(yè)機器人一樣,不斷向智能化和多樣化方向發(fā)展。

At present, the international robot industry is increasing scientific research efforts to study the common technology of robots. From the perspective of the development trend of robot technology, welding robots, like other industrial robots, continue to develop in the direction of intelligence and diversification.

焊接機器人在機器人的用途中一直占據(jù)著主導地位,盡管近年來在國內(nèi)得到了迅速發(fā)展,但在世界范圍內(nèi)來看,它的應用還處于發(fā)展上升期,我們要做的工作還很多。

Welding robot has been playing a leading role in the application of robot. Although it has been developed rapidly in China in recent years, its application is still in the rising stage in the world, and we still have a lot of work to do.