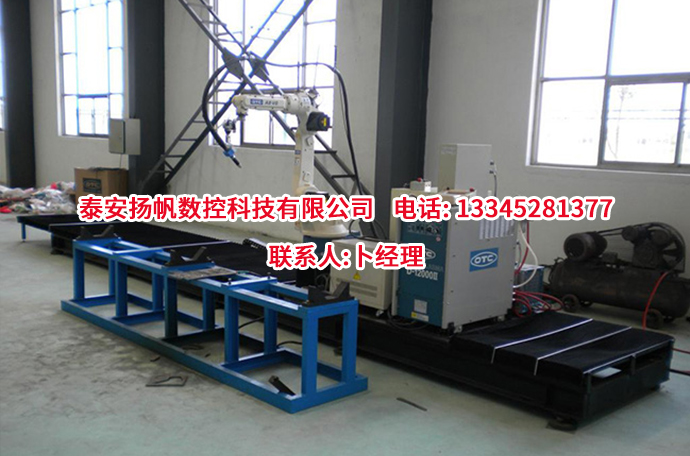

選擇數(shù)控焊接設(shè)備從設(shè)備結(jié)構(gòu)開(kāi)始考慮

來(lái)源:http://maxsenz.com/ 發(fā)布時(shí)間:2023-04-04 瀏覽次數(shù):0

為了方便工作的開(kāi)展,在選擇數(shù)控焊接設(shè)備類型的時(shí)候,要從多個(gè)方面綜合來(lái)進(jìn)行考慮,比如說(shuō),設(shè)備的類型,設(shè)備的基本結(jié)構(gòu)等等。下面就詳細(xì)為您介紹下設(shè)備結(jié)構(gòu)內(nèi)容。

For the convenience of work, when selecting the type of CNC welding equipment, multiple aspects should be considered comprehensively, such as the type of equipment, the basic structure of the equipment, and so on. Below is a detailed introduction to the equipment structure.

1、焊接電源,其輸出功率和焊接特性應(yīng)與擬用的焊接工藝方法相匹配,并裝有與主控制器相連接的接口。

1. The output power and welding characteristics of the welding power supply should match the proposed welding process method, and be equipped with an interface connected to the main controller.

2、送絲機(jī)及其控制與調(diào)速系統(tǒng),對(duì)于送絲速度控制精度要求較高送絲機(jī),其控制電路應(yīng)加測(cè)速反饋。

2. The wire feeder and its control and speed regulation system require high precision in wire feeding speed control. The control circuit of the wire feeder should be equipped with speed feedback.

3、焊接機(jī)頭用其移動(dòng)機(jī)構(gòu),其由焊接機(jī)頭,焊接機(jī)頭支承架,懸掛式拖板等組成,低于焊頭機(jī)構(gòu),其驅(qū)動(dòng)系統(tǒng)應(yīng)采用裝有編碼器的伺服電動(dòng)機(jī)。

3. The welding head is equipped with a moving mechanism, which is composed of a welding head, a welding head support frame, a suspended carriage, etc. It is lower than the welding head mechanism, and its driving system should use a servo motor equipped with an encoder.

4、焊件移動(dòng)或變位機(jī)構(gòu),如焊接滾輪架,頭尾架翻轉(zhuǎn)機(jī),回轉(zhuǎn)平臺(tái)和變位機(jī)等,移動(dòng)變位機(jī)構(gòu)應(yīng)配伺服電動(dòng)機(jī)驅(qū)動(dòng)。

4. Weldment movement or displacement mechanisms, such as welding roller frames, head and tail frame flippers, rotary platforms, and displacement machines, should be equipped with servo motor drives for movement and displacement mechanisms.

5、焊接機(jī)器人,又稱機(jī)械手臂,是山東數(shù)控焊接設(shè)備的重要組成部分。其主要工作包括:焊接、切割、熱噴涂、搬運(yùn)等。

5. Welding robots, also known as robotic arms, are an important component of Shandong CNC welding equipment. Its main tasks include welding, cutting, thermal spraying, handling, etc.

6、主控制器,亦稱系統(tǒng)控制器,主要用于各組成部分的聯(lián)動(dòng)控制,焊接程序的控制,主要焊接參數(shù)的設(shè)定,調(diào)整和顯示。必要時(shí)可擴(kuò)展故障診斷和人機(jī)對(duì)話等控制功能。

6. The main controller, also known as the system controller, is mainly used for the linkage control of various components, the control of welding programs, and the setting, adjustment, and display of main welding parameters. If necessary, control functions such as fault diagnosis and human-machine dialogue can be expanded.

7、焊頭導(dǎo)向或跟蹤機(jī)構(gòu),弧壓自動(dòng)控制器,焊槍擺器和監(jiān)控系統(tǒng)。

7. Welding head guidance or tracking mechanism, arc pressure automatic controller, welding gun pendulum and monitoring system.

8、焊件夾緊機(jī)構(gòu)。

8. Weldment clamping mechanism.

9、計(jì)算機(jī)軟件,焊接設(shè)備中常用的計(jì)算機(jī)軟件有:編程軟件,功能軟件,工藝方法軟件和系統(tǒng)等。

9. Computer software, commonly used in welding equipment, includes programming software, functional software, process method software, and expert systems.

在選擇數(shù)控焊接設(shè)備的時(shí)候,要從多個(gè)方面綜合進(jìn)行考慮,比如設(shè)備的結(jié)構(gòu)等方面來(lái)判斷,進(jìn)而選到合適的產(chǎn)品進(jìn)行運(yùn)用。如果大家不知道該如何選擇的話,可以參考上述內(nèi)容進(jìn)行挑選。更多事項(xiàng)就來(lái)我們網(wǎng)站http://maxsenz.com咨詢!

When selecting CNC welding equipment, it is necessary to consider multiple aspects comprehensively, such as the structure of the equipment, and then select suitable products for application. If you don't know how to choose, you can refer to the above content for selection. For more information, come to our website http://maxsenz.com consulting service