自動焊接設(shè)備的運(yùn)轉(zhuǎn)及相關(guān)操作

來源:http://maxsenz.com/ 發(fā)布時(shí)間:2023-02-11 瀏覽次數(shù):0

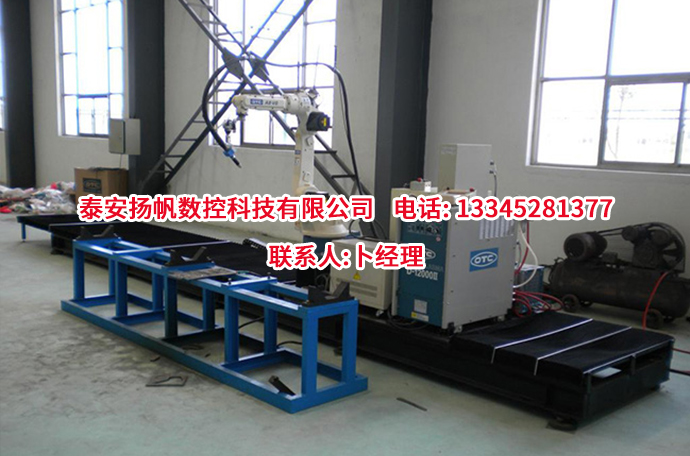

自動焊接設(shè)備是一種為焊接提供一定電源特性的設(shè)備,廣泛應(yīng)用于現(xiàn)代工業(yè)生產(chǎn)。自動焊機(jī)的裝置和操作一定符合技術(shù)規(guī)范和規(guī)范,這直接關(guān)系到焊接操作的作用。那么今天小編就帶大家一起了解一下山東自動焊接設(shè)備的運(yùn)轉(zhuǎn)及相關(guān)操作。

Automatic welding equipment is a kind of equipment that provides certain power characteristics for welding and is widely used in modern industrial production. The device and operation of automatic welding machine must conform to the technical specifications and specifications, which is directly related to the role of welding operation. So today, Xiaobian will take you to understand the operation and related operations of Shandong automatic welding equipment.

1.按要求裝置好電加熱式CO2氣體減壓器

1. Install the electrically heated CO2 gas pressure reducer as required

2.運(yùn)用前有必要先預(yù)熱5-10分鐘;

2. It is necessary to preheat for 5-10 minutes before use;

3.緩緩將氣瓶上的閥門打開(速度約5度/秒),這時(shí)可觀察到壓力表的指針慢慢抬起,然后停在適宜的刻度上。

3. Slowly open the valve on the cylinder (at a speed of about 5 degrees/second), and then observe that the pointer of the pressure gauge slowly rises, and then stops on the appropriate scale.

4.閉合設(shè)備電氣箱空氣開關(guān)對設(shè)備上電,檢查電氣箱和機(jī)身是否漏電(發(fā)現(xiàn)漏電須掃除后進(jìn)行下一步操作)。

4. Close the air switch of the electrical box of the equipment to power on the equipment, and check whether the electrical box and the machine body have leakage (if any leakage is found, clean it up and carry out the next operation).

6.檢查減速箱是否加注潤滑油,發(fā)現(xiàn)異常須按本減速機(jī)保護(hù)規(guī)范處理。

6. Check whether the gearbox is filled with lubricating oil. If any abnormality is found, it shall be handled according to the reducer protection specification.

8.在操作面板上挑選正確作業(yè)狀態(tài):“調(diào)試”檔位合適本機(jī)手動操控作業(yè);“自動”檔位合適程序化自動焊接作業(yè)。

8. Select the correct operation status on the operation panel: the "commissioning" gear is suitable for manual operation of the machine; "Automatic" gear is suitable for programmed automatic welding operation.

9.調(diào)整好適當(dāng)參數(shù)(作業(yè)臺回轉(zhuǎn)速度)和正確轉(zhuǎn)向,啟動設(shè)備進(jìn)行正常操作和作業(yè)。

9. Adjust the appropriate parameters (table rotation speed) and correct steering, and start the equipment for normal operation and operation.

10.能夠在焊機(jī)的操控面板上進(jìn)行功用挑選和部分參數(shù)設(shè)定。

10. Be able to select functions and set some parameters on the control panel of the welding machine.

11.焊機(jī)的操控面板所對應(yīng)的功用有指示燈顯示,在運(yùn)用過程中對應(yīng)的指示燈被點(diǎn)亮即可進(jìn)行對應(yīng)的操作。(特別留意當(dāng)焊機(jī)過熱時(shí),機(jī)內(nèi)溫度指示燈會被點(diǎn)亮,此刻留意操控好焊機(jī)的運(yùn)用時(shí)間或暫停運(yùn)用該設(shè)備)

11. The function corresponding to the control panel of the welding machine has indicator light display, and the corresponding operation can be carried out when the corresponding indicator light is lit during operation. (Pay special attention to that when the welding machine overheats, the temperature indicator in the machine will be lit. At this moment, pay attention to the operation time of the welding machine or suspend the use of the equipment)

以上就是對自動焊接設(shè)備運(yùn)轉(zhuǎn)以及未來發(fā)展方向的詳細(xì)介紹,希望通過介紹,大家對自動焊接有了更加深入的了解,想要了解更多關(guān)于自動焊接發(fā)展前景以及創(chuàng)新技術(shù),請點(diǎn)擊官網(wǎng)http://maxsenz.com!

The above is a detailed introduction to the operation of automatic welding equipment and its future development direction. I hope that through the introduction, you can have a deeper understanding of automatic welding. If you want to know more about the development prospect and innovative technology of automatic welding, please click the official website http://maxsenz.com !