數(shù)控切割機日常使用的一些技巧

來源:http://maxsenz.com/ 發(fā)布時間:2022-07-19 瀏覽次數(shù):0

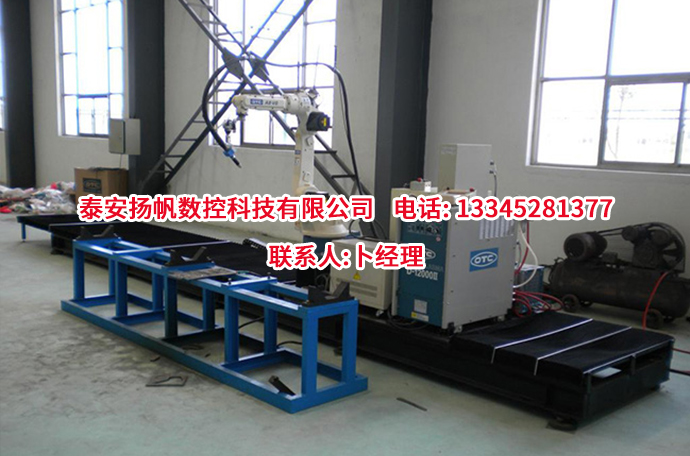

數(shù)控切割機在切割能源和數(shù)控控制系統(tǒng)兩方面取得了長足的發(fā)展,切割能源已由單一的火焰能源切割發(fā)展為多種能源切割方式,下面為大家總結了一些數(shù)控切割機日常使用的一些技巧。

CNC cutting machine has made great progress in cutting energy and CNC control system. Cutting energy has developed from a single flame energy cutting to a variety of energy cutting methods. Here are some skills of daily use of CNC cutting machine.

1、切割應從邊緣開始;盡可能從邊緣開始切割,而不要穿孔切割。采用邊緣作為起始點會延長消耗件的壽命,正確的方法是將噴嘴直接對準工件邊緣后再啟動等離子弧。

1. Cutting shall start from the edge; As far as possible, cut from the edge rather than through the hole. Using the edge as the starting point will prolong the service life of the consumer. The correct method is to align the nozzle directly with the edge of the workpiece and then start the plasma arc.

2、減少不必要的“起弧(或導弧)”時間;起弧時噴嘴和電極的消耗都非常快,在開始前,應將割炬放在切割金屬行走距離內。

2. Reduce unnecessary "arc striking (or arc guiding)" time; The consumption of nozzle and electrode is very fast during arc starting. Before starting, the cutting torch should be placed within the walking distance of cutting metal.

3、噴嘴不要過載使用;讓噴嘴過載(即超過噴嘴的工作電流),將使噴嘴很快損壞。電流強度應為噴嘴的工作電流的95%為宜。例如:100A的噴嘴的電流強度應設定為95A。

3. Do not overload the nozzle; Overloading the nozzle (i.e. exceeding the working current of the nozzle) will quickly damage the nozzle. The current intensity should be 95% of the working current of the nozzle. For example, the current intensity of 100A nozzle should be set to 95A.

4、采用合理的切距;按照使用說明書的要求,采用合理的切距,切距即切割噴嘴與工件表面的距離,當穿孔時,盡量采用正常切距的2倍距離或采用等離子弧所能傳遞的大高度。

4. Adopt reasonable tangent distance; According to the requirements of the instruction manual, adopt a reasonable cutting distance, which is the distance between the cutting nozzle and the workpiece surface. When punching, try to use a distance twice the normal cutting distance or a large height that can be transferred by the plasma arc.

5、穿孔厚度應在機器系統(tǒng)的允許范圍內;切割機不能在超過工作厚度的鋼板上穿孔,通常的穿孔厚度為正常切割厚度的1/2。

5. The perforation thickness should be within the allowable range of the machine system; The cutting machine cannot punch on the steel plate that exceeds the working thickness, and the usual perforation thickness is 1/2 of the normal cutting thickness.

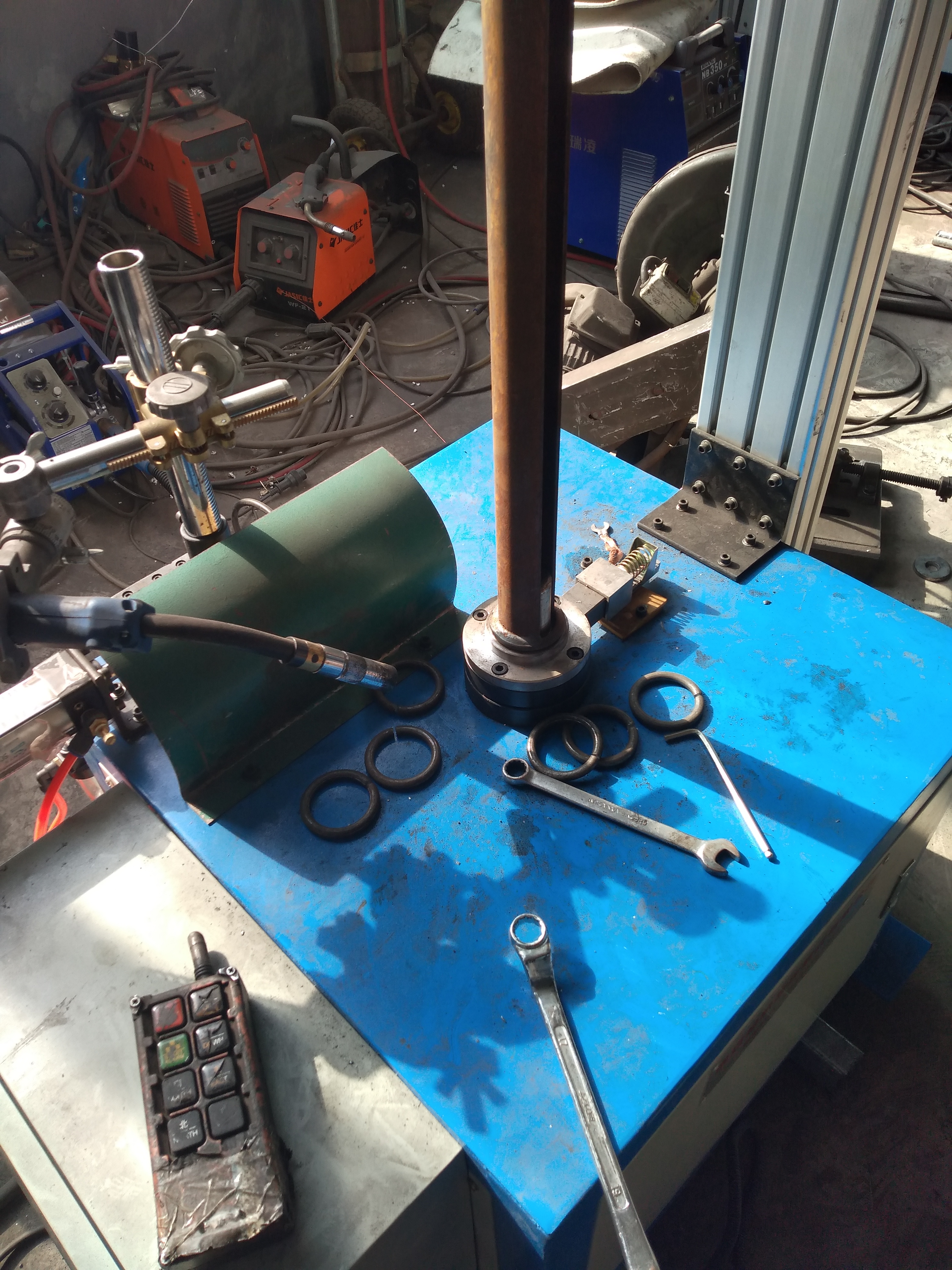

6、盡量保持數(shù)控切割機割炬和消耗件清潔:在割炬和消耗件上的任何臟物都會極大地影響等離子系統(tǒng)的功能。更換消耗件時要將其放在干凈的絨布上,要經(jīng)常檢查割炬的連接羅紋,用過氧化氫類清潔劑清洗電極接觸面和噴嘴。

6. Try to keep the cutting torch and consumables of the CNC cutting machine clean: any dirt on the cutting torch and consumables will greatly affect the function of the plasma system. When replacing consumer parts, put them on a clean flannelette, often check the connecting rib of the cutting torch, and clean the electrode contact surface and nozzle with hydrogen peroxide detergent.

7、盡量少穿孔切割,穿孔是鋼水反濺會傷及噴嘴,這是割嘴損壞的主要原因之一,如果一定要穿孔切割,在穿孔處用鉆頭打預鉆孔,在從預鉆孔處開始切割;

7. Try to minimize perforation and cutting. Perforation is one of the main reasons for the damage of the cutting nozzle because the back splashing of molten steel will damage the nozzle. If perforation and cutting are necessary, pre drill the hole with a drill at the perforation and cut from the pre drill;

8、盡量在切割機額定的正常切割厚度范圍內切割,盡量不要在極限切割厚度上切割,國產(chǎn)切割機的正常切割厚度一般是生產(chǎn)廠家標注的大切割厚度的60%,盡量在這個厚度范圍內切割,就能保護割嘴;

8. Try to cut within the rated normal cutting thickness of the cutting machine, and try not to cut at the limit cutting thickness. The normal cutting thickness of domestic cutting machines is generally 60% of the large cutting thickness marked by the manufacturer, and try to cut within this thickness range, so as to protect the cutting nozzle;

9、山東數(shù)控焊接設備廠家認為割嘴到鋼板的距離盡量保持恒定,一般在3-8mm左右,太遠了不但耗電量太大,切割穿透能力力會下降,而且相對比較消耗電極,使電極使用壽命下降;太近了那更簡單,非常費噴嘴,噴嘴的使用壽命會成倍的下降,甚與上去即被燒掉。

9. Shandong CNC welding equipment manufacturers believe that the distance between the cutting nozzle and the steel plate should be kept as constant as possible, generally about 3-8mm. If it is too far away, not only the power consumption is too large, the cutting penetration capacity will decline, but also the electrode is relatively consumed, which will reduce the service life of the electrode; If it is too close, it will be simpler, and it will cost a lot of nozzles. The service life of the nozzles will be doubled and even burned up.

以上就是正確使用數(shù)控焊接機以及在日常使用中的一些小技巧了,希望可以幫您解決使用中發(fā)生的一些問題,更多問題您可以來關注我們網(wǎng)站http://maxsenz.com尋求解答。

The above is the correct use of CNC welding machine and some tips in daily use. I hope it can help you solve some problems in use. For more problems, you can pay attention to our website http://maxsenz.com Seek answers.