數(shù)控焊接設(shè)備進行調(diào)試焊接參數(shù)的操作

來源:http://maxsenz.com/ 發(fā)布時間:2023-03-21 瀏覽次數(shù):0

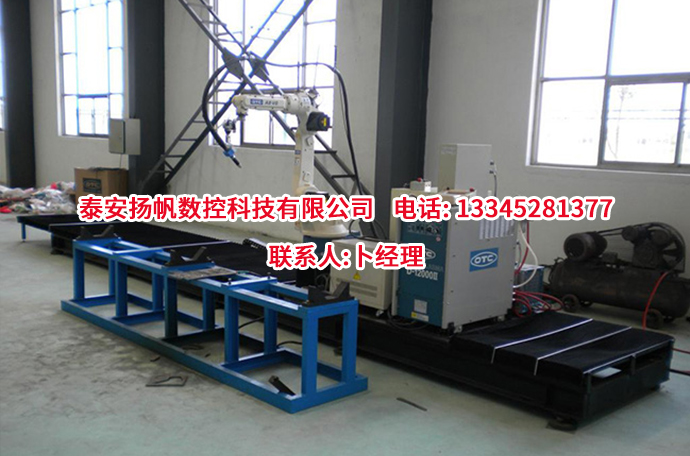

數(shù)控焊接設(shè)備是用于焊接作業(yè)的機械設(shè)備,自動化和智能化水平較高,在焊接生產(chǎn)中可以提高焊接效率的同時穩(wěn)定焊接質(zhì)量,調(diào)試方法影響焊接質(zhì)量的穩(wěn)定性,調(diào)試工人在焊接生產(chǎn)中需要根據(jù)工件的規(guī)格進行調(diào)試焊接參數(shù),焊接參數(shù)主要有:

CNC welding equipment is a mechanical equipment used for welding operations, with a high level of automation and intelligence. It can improve welding efficiency and stabilize welding quality during welding production. Debugging methods affect the stability of welding quality. Debugging workers need to adjust welding parameters according to the specifications of the workpiece during welding production. The main welding parameters include:

1、焊接電流、電壓。在設(shè)置焊接電流的時候,小編建議較細的焊條就需要較小的焊接電流,較粗的焊條就需要選擇較大的焊接電流。焊接電流通常是與焊接電壓一起來設(shè)置的。焊接電流和電壓需要配合穩(wěn)定,減少焊接缺陷的發(fā)生率。

1. Welding current and voltage. When setting the welding current, the editor suggests that thinner electrodes require a smaller welding current, while thicker electrodes require a larger welding current. The welding current is usually set together with the welding voltage. The welding current and voltage need to be coordinated and stable to reduce the incidence of welding defects.

2、焊接速度。焊接速度過快,山東數(shù)控焊接設(shè)備就容易出現(xiàn)漏焊、少焊等狀況,焊接速度過慢,導(dǎo)致企業(yè)生產(chǎn)周期緩慢,影響焊接進程,設(shè)置焊接速度需要根據(jù)焊件的規(guī)格,選擇合適的速度進行焊接,在穩(wěn)定焊接質(zhì)量的基礎(chǔ)上提高生產(chǎn)速度。

2. Welding speed. If the welding speed is too fast, Shandong CNC welding equipment is prone to situations such as missing welds and insufficient welds. If the welding speed is too slow, it will lead to slow production cycles and affect the welding process. To set the welding speed, it is necessary to select an appropriate speed for welding based on the specifications of the weldment, and improve the production speed on the basis of stable welding quality.

3、機械臂擺動幅度。數(shù)控焊接設(shè)備在焊接中,根據(jù)焊縫的位置進行擺動,設(shè)置擺動幅度的時候?qū)⒑笜屵M行適當(dāng)?shù)那刂x,可以減少焊點飛濺、焊縫熔深較大。

3. The swing amplitude of the mechanical arm. During welding, CNC welding equipment swings according to the position of the weld. When setting the swing amplitude, the welding gun is properly adjusted to reduce weld spatter and large weld penetration.

4、焊接方向。數(shù)控焊接設(shè)備有兩種焊接方向,分別是前進法和后退法,前進法就是電弧與待焊工件不直接接觸,后退法是電弧直接作用在工件上,兩種焊接方向根據(jù)焊縫的方向進行設(shè)置即可。

4. Welding direction. CNC welding equipment has two welding directions, namely, forward method and backward method. Forward method means that the arc does not directly contact the workpiece to be welded, and backward method means that the arc directly acts on the workpiece. The two welding directions can be set according to the direction of the weld.

調(diào)試成功后的數(shù)控焊接設(shè)備可進行批量生產(chǎn),在生產(chǎn)中人員需要遠離焊接范圍,通過內(nèi)外傳感器實時監(jiān)測數(shù)控焊接設(shè)備運行情況以及焊接質(zhì)量,出現(xiàn)問題及時停機檢查。

After successful debugging, the CNC welding equipment can be mass produced. During production, personnel need to stay away from the welding range, monitor the operation of the CNC welding equipment and welding quality in real time through internal and external sensors, and timely stop the machine for inspection if problems occur.

以上就是數(shù)控焊接設(shè)備的調(diào)試參數(shù)方法,調(diào)試成功后的數(shù)控焊接設(shè)備可以穩(wěn)定焊接質(zhì)量,提高焊接效率。更多相關(guān)內(nèi)容就來我們網(wǎng)站http://maxsenz.com進行咨詢了解!

The above is the method for debugging parameters of CNC welding equipment. After successful debugging, CNC welding equipment can stabilize welding quality and improve welding efficiency. For more relevant content, please visit our website http://maxsenz.com Consult and learn!