數(shù)控切割機(jī)的正確使用非常關(guān)鍵

來(lái)源:http://maxsenz.com/ 發(fā)布時(shí)間:2022-08-23 瀏覽次數(shù):0

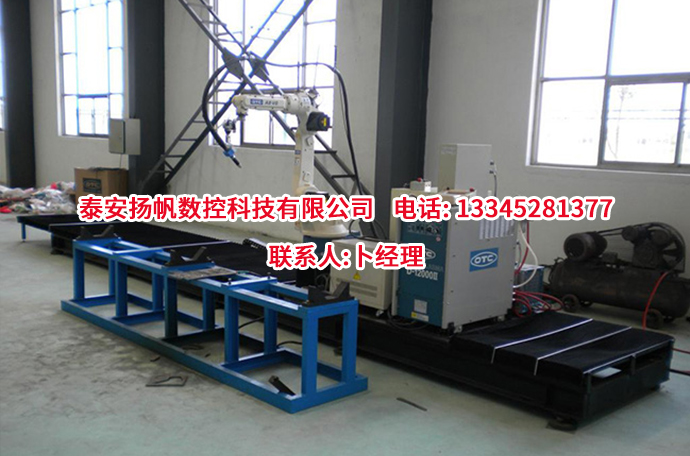

數(shù)控切割機(jī)在切割能源和數(shù)控控制系統(tǒng)兩方面取得了長(zhǎng)足的發(fā)展,切割能源已由單一的火焰能源切割發(fā)展為多種能源,那么山東數(shù)控焊接設(shè)備廠家就來(lái)為您講講數(shù)控切割機(jī)的正確使用吧。

CNC cutting machine has made great progress in cutting energy and CNC control system. Cutting energy has developed from single flame energy cutting to multiple energy sources. Then Shandong CNC welding equipment manufacturer will tell you about the correct use of CNC cutting machine.

1、合上配電柜內(nèi)開(kāi)關(guān);

1. Close the switch in the distribution cabinet;

2、打開(kāi)操作面板上電源鎖,按下電源按鈕,給CNC供電;接通除塵器電源,檢查控制箱面板上的指示燈是否正常;

2. Open the power lock on the operation panel and press the power button to supply power to the CNC; Turn on the power supply of the dust collector and check whether the indicator light on the control box panel is normal;

3、CNC進(jìn)行內(nèi)部自診斷,確認(rèn)沒(méi)顯示錯(cuò)誤信息;

3. CNC conducts internal self diagnosis and confirms that no error information is displayed;

4、合上伺服柜內(nèi)的開(kāi)關(guān),按下操作面板上的伺服開(kāi)按鈕,給伺服系統(tǒng)供電,轉(zhuǎn)動(dòng)控制柜面板上脈沖旋鈕開(kāi)的位置對(duì)濾筒進(jìn)行反沖,檢查脈沖是否正常;

4. Close the switch in the servo cabinet, press the servo on button on the operation panel to supply power to the servo system, turn the pulse knob on the control cabinet panel to the on position to recoil the filter cartridge, and check whether the pulse is normal;

5、試操作,確認(rèn)面板上的各開(kāi)關(guān)、按鈕靈活、可靠檢查卸灰插板閥是否正常;

5. Test operation, confirm that the switches and buttons on the panel are flexible and reliable, and check whether the ash unloading plug-in valve is normal;

6、試運(yùn)行機(jī)器,確認(rèn)機(jī)器運(yùn)行平穩(wěn),各限位及緊急按鈕可靠;

6. Test run the machine and confirm that the machine runs smoothly and that the limit and emergency buttons are reliable;

7、噴粉劃線在切割前進(jìn)行,注意鋅粉易爆,注意避免飛揚(yáng),

7. Powder spraying and scribing shall be carried out before cutting. Pay attention to the explosion of zinc powder and avoid flying,

8、等離子切割時(shí),需要注意在自動(dòng)點(diǎn)火時(shí),人員要遠(yuǎn)離點(diǎn)火高壓線圈;

8. During plasma cutting, attention shall be paid to keep personnel away from ignition high-voltage coil during automatic ignition;

手動(dòng)將割炬定到起始位置;在CNC上選定切割程序,并完成工作配置:切割速度、割縫補(bǔ)償?shù)葍?nèi)容;按“GO”按鈕開(kāi)始切割;按操作說(shuō)明書(shū)對(duì)切割中出現(xiàn)的不同問(wèn)題,進(jìn)行相應(yīng)處理,直到切割完成。更多相關(guān)事項(xiàng)就來(lái)我們網(wǎng)站http://maxsenz.com看看吧。

Manually set the cutting torch to the starting position; Select cutting program on CNC and complete work configuration: cutting speed, slit compensation, etc; Press the "go" button to start cutting; According to the operating instructions, different problems in cutting shall be handled accordingly until the cutting is completed. For more information, please visit our website http://maxsenz.com Let's see.