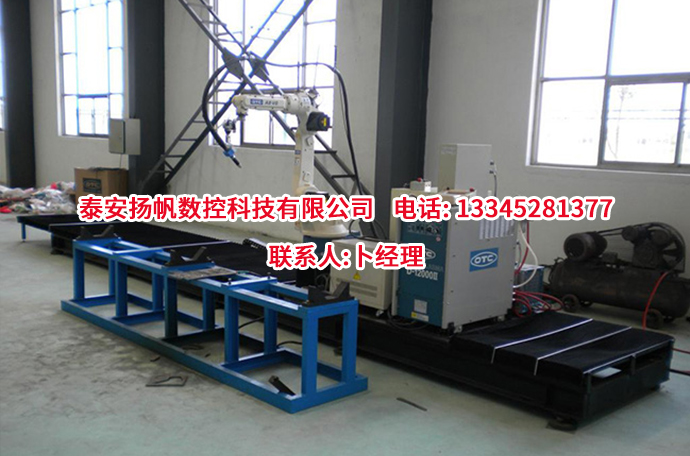

自動(dòng)焊接設(shè)備故障維修之直接短接法

來(lái)源:http://maxsenz.com/ 發(fā)布時(shí)間:2022-07-28 瀏覽次數(shù):0

設(shè)備電路或焊接設(shè)備的故障大致歸納為短路、過(guò)載、斷路、接地、接線錯(cuò)誤、焊接設(shè)備的電磁及機(jī)械部分故障、元器件老化等七類。諸類故障中出現(xiàn)較多的為斷路故障,包括導(dǎo)線斷路、虛連、松動(dòng)、觸點(diǎn)接觸不良、虛焊、假焊以及熔斷器熔斷等。

The faults of equipment circuit or welding equipment can be roughly divided into seven categories: short circuit, overload, open circuit, grounding, wrong wiring, electromagnetic and mechanical part faults of welding equipment, aging of components and parts. Many of these faults are open circuit faults, including wire open circuit, virtual connection, looseness, poor contact of contacts, false soldering, false soldering and fuse fusing.

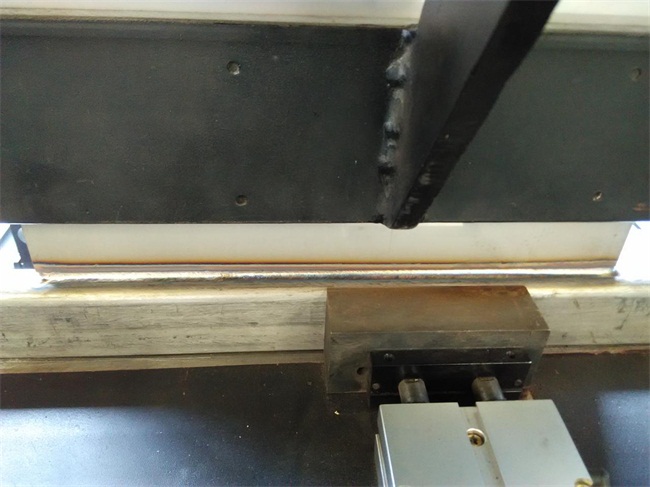

對(duì)山東自動(dòng)焊接設(shè)備的這類故障除用電阻法、電壓法檢查外,還有一種更為簡(jiǎn)單可靠的方法,就是短接法。即用一根良好絕緣的導(dǎo)線,將所懷疑的斷路部位短路接起來(lái),如短接到某處,電路工作恢復(fù)正常,說(shuō)明該處斷路。具體操作可分為局部短接法和長(zhǎng)短接法。

In addition to the resistance method and voltage method, there is a simpler and more reliable method to check such faults of Shandong automatic welding equipment, that is, the short-circuit method. That is, use a well insulated wire to short-circuit the suspected open circuit part. If it is short circuited to a certain place, the circuit will return to normal, indicating that there is an open circuit. The specific operation can be divided into local short connection method and long short connection method.

對(duì)于連續(xù)燒壞的元器件應(yīng)機(jī)明原因后再進(jìn)行更換;電壓測(cè)量時(shí)應(yīng)考慮到導(dǎo)線的壓降;不違反設(shè)備性能和焊接設(shè)備作用的原則,修復(fù)的焊接設(shè)備初次試通電工作前,

The components and parts that are continuously burnt out shall be replaced after the cause is found out; The voltage drop of the conductor shall be considered during voltage measurement; Do not violate the principle of equipment performance and the role of welding equipment. Before the first trial energization of the repaired welding equipment,

對(duì)氣體保護(hù)焊和點(diǎn)焊、縫焊、凸焊及對(duì)焊等設(shè)備應(yīng)該先通氣、通水,應(yīng)該加油的部位還需要加油,周圍障礙物,通電工作時(shí)手不得離開(kāi)電源開(kāi)關(guān)停止按鈕,保險(xiǎn)期間應(yīng)使用等量或略小于額定值的電流;還須注意測(cè)量?jī)x器儀表?yè)跷坏倪x擇。

Gas shielded welding, spot welding, seam welding, projection welding, butt welding and other equipment should be ventilated and watered first. The parts that should be oiled also need to be oiled, and the surrounding obstacles should be removed. When working with power on, hands should not leave the power switch stop button. During the insurance period, the same amount of current or slightly less than the rated value should be used; Attention should also be paid to the selection of gear of measuring instruments.

以上一些檢查方法,要視情況靈活運(yùn)用,但須遵守操作規(guī)章,防止在設(shè)備維修過(guò)程中出現(xiàn)人身、設(shè)備傷害事故,并且盡可能兩人操作和監(jiān)護(hù)。

The above inspection methods should be used flexibly according to the situation, but the safety operation rules must be observed to prevent personal and equipment injury accidents in the process of equipment maintenance, and two people should operate and monitor as much as possible.

對(duì)焊接設(shè)備故障的檢查和維修排除,要按照相關(guān)要求做好記錄。方便以后類似故障發(fā)生后的檢查、日常維護(hù)保養(yǎng)和故障排除的經(jīng)驗(yàn)積累,更多相關(guān)內(nèi)容就來(lái)我們網(wǎng)站http://maxsenz.com咨詢了解吧。

The inspection, maintenance and troubleshooting of welding equipment shall be recorded according to relevant requirements. It is convenient to accumulate experience in inspection, daily maintenance and troubleshooting after similar faults occur in the future. More relevant content can be found on our website http://maxsenz.com Consult and understand.

上一篇:焊接機(jī)械手操作及保養(yǎng)規(guī)程

下一篇:維修時(shí)應(yīng)詳細(xì)觀察焊接設(shè)備本身