自動(dòng)焊接專機(jī)的日常保養(yǎng)八大事項(xiàng)

來(lái)源:http://maxsenz.com/ 發(fā)布時(shí)間:2023-07-15 瀏覽次數(shù):0

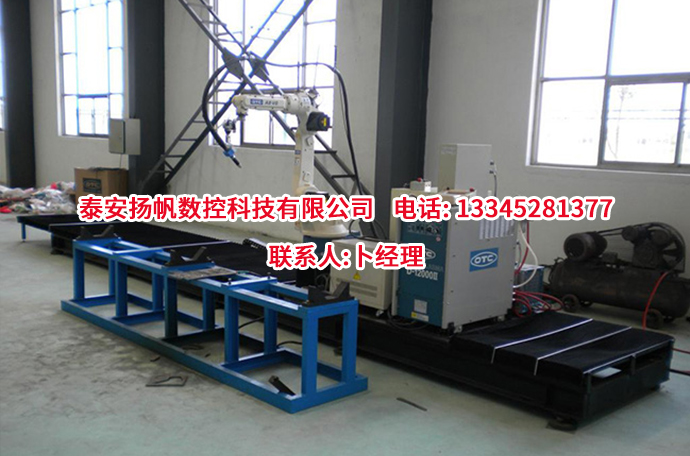

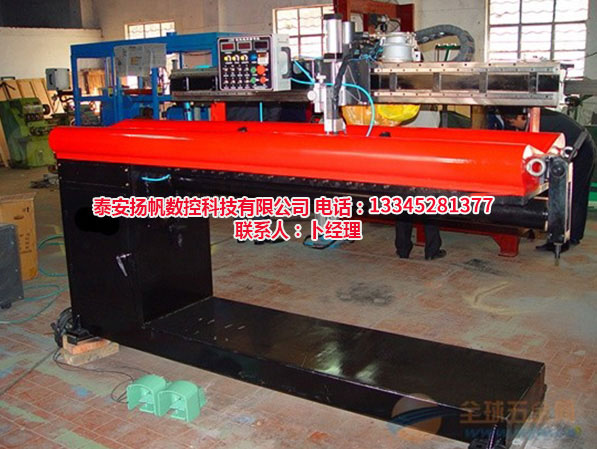

自動(dòng)焊接專機(jī)是用于自動(dòng)化生產(chǎn)的,要求人工或者機(jī)械手上下工件,焊接工裝夾具自動(dòng)將工件固定,定位,自動(dòng)啟動(dòng)焊接電源的電弧,自動(dòng)送絲和焊槍或工件的自動(dòng)移動(dòng),焊接完成后自動(dòng)退回,人工或機(jī)械手取下工件,其組成主要由焊接系統(tǒng)、機(jī)械系統(tǒng)、電氣控制系統(tǒng)構(gòu)成。那么山東焊接專機(jī)如何保養(yǎng)呢?

The special automatic welding machine is used for automatic production. It requires manual or manipulator to mount and lower the workpiece. The welding fixture automatically fixes and positions the workpiece, automatically starts the arc of the Welding power supply, automatically feeds wire and automatically moves the welding gun or workpiece, automatically returns after welding, and manually or manually removes the workpiece. It is mainly composed of welding system, mechanical system, and electrical control system. So how to maintain the Shandong welding machine?

1.自動(dòng)焊接專機(jī)操作機(jī)中鏈條為易損件,每年少拆下檢查一次,及時(shí)處理。

1. The chain in the automatic welding machine operator is a vulnerable component, which should be removed and inspected at least once a year for timely handling.

2.各行程開關(guān)的動(dòng)作靈活性、可靠性要經(jīng)常檢查,以免有松動(dòng)、損壞。

2. The flexibility and reliability of each travel switch should be regularly checked to avoid looseness and damage.

3.電路接頭要經(jīng)常檢查,保持連接牢固,插接可靠。

3. Circuit connectors should be regularly inspected to ensure they are securely connected and reliably plugged in.

4.工作站控制器及手操器內(nèi)的塵土要三個(gè)月一次用壓縮空氣吹 。

4. The dust inside the workstation controller and manual operator should be blown with compressed air every three months.

5.電器、旋鈕、開關(guān)要經(jīng)常檢查,保持清潔和良好的接觸,以免誤動(dòng)作。

5. Electrical appliances, knobs, and switches should be regularly inspected to maintain cleanliness and good contact to avoid misoperation.

6.各導(dǎo)軌、滑架、絲杠及螺母等運(yùn)動(dòng)部位經(jīng)常檢查清理,防止塵土堆積而影響運(yùn)動(dòng)部位的靈活運(yùn)動(dòng)。

6. Regularly inspect and clean the moving parts such as guide rails, sliding frames, screws, and nuts to prevent dust accumulation from affecting the flexible movement of the moving parts.

7.各滑動(dòng)導(dǎo)軌的結(jié)合面不允許碰撞、磨損。絲杠、齒條等關(guān)鍵運(yùn)動(dòng)部件要經(jīng)常檢查避免磨損情況。

7. The joint surface of each sliding guide rail is not allowed to collide or wear. Key moving components such as screws and racks should be regularly inspected to avoid wear and tear.

8.自動(dòng)焊接操作機(jī)各運(yùn)動(dòng)部位、導(dǎo)軌與滾輪應(yīng)涂潤(rùn)滑脂,閉式傳動(dòng)部位應(yīng)注潤(rùn)滑油,以保持部件運(yùn)動(dòng)靈活;是對(duì)平心輪、偏心輪部件的維護(hù),保證其緊固,確保橫臂運(yùn)動(dòng)平直。

8. Each moving part, guide rail, and roller of the automatic welding operator should be coated with lubricating grease, and the closed transmission part should be injected with lubricating oil to maintain flexible movement of the components; The key is to maintain the flat center wheel and eccentric wheel components, ensuring their fastening and ensuring the smooth movement of the cross arm.

自動(dòng)焊接專機(jī)的日常保養(yǎng)八大事項(xiàng)相關(guān)內(nèi)容就講解到這里了,希望能夠給您好的幫助,更多事項(xiàng)就來(lái)我們網(wǎng)站http://maxsenz.com進(jìn)行咨詢吧!

That's all for the daily maintenance of the automatic welding machine. We hope it can be helpful to you. For more information, please come to our website http://maxsenz.com Let's consult!

上一篇:數(shù)控焊接設(shè)備該如何清潔維護(hù)

下一篇:焊接專機(jī)與其他常見的焊接設(shè)備作對(duì)比