焊接專機(jī)的機(jī)械系統(tǒng)的構(gòu)成思路

來源:http://maxsenz.com/ 發(fā)布時(shí)間:2022-10-20 瀏覽次數(shù):0

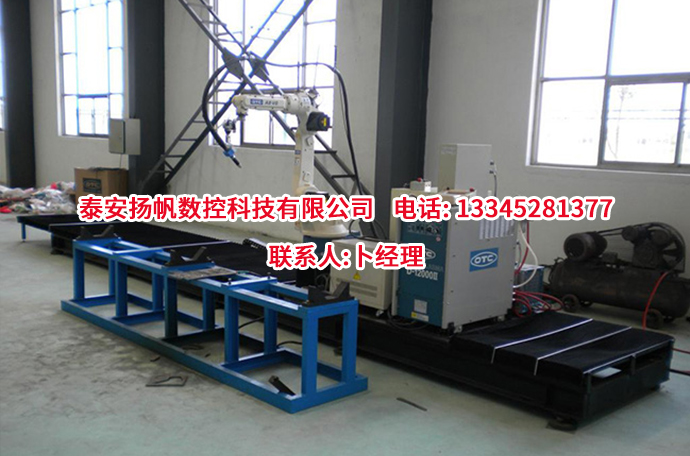

焊接專機(jī)的機(jī)械系統(tǒng)主要由床身機(jī)構(gòu)、工裝夾具及工件輔助支撐機(jī)構(gòu)、焊槍微調(diào)機(jī)構(gòu)、焊接工件或者焊槍移動(dòng)機(jī)構(gòu)等。由于各類焊接工件的形狀,尺寸,焊縫位置等等的不同,每個(gè)設(shè)計(jì)人員的設(shè)計(jì)思路不同,所以山東焊接專機(jī)的樣式也千奇百怪,下面我們?cè)敿?xì)講解構(gòu)成思路。

The mechanical system of the special welding machine mainly consists of the machine bed mechanism, fixture and workpiece auxiliary support mechanism, welding gun fine adjustment mechanism, welding workpiece or welding gun moving mechanism, etc. Due to the different shapes, sizes, weld positions, etc. of various welding workpieces, each designer has different design ideas, so the styles of Shandong special welding machine are also various. Let's explain the composition ideas in detail.

床身機(jī)構(gòu):床身主要對(duì)設(shè)備起支撐作用,可以用鑄造件或者焊接件構(gòu)成。由于鑄造件生產(chǎn)周期長(zhǎng),成本高,所以基本上采用型材和鋼板焊接后,經(jīng)退火、精加工而成,可以快速制造和成本低,得到大量使用。

Machine bed mechanism: The machine bed is mainly used to support the equipment, and can be made of casting parts or welding parts. Because of the long production cycle and high cost of castings, they are basically made of sections and steel plates after welding, annealing and finishing, which can be rapidly manufactured with low cost and widely used.

工裝夾具及輔助支撐機(jī)構(gòu):可以根據(jù)工件的加工面或定位孔,固定工件的相對(duì)位置,可以采用手動(dòng)、氣動(dòng)、電動(dòng)、液壓控制夾具運(yùn)動(dòng),實(shí)現(xiàn)裝夾和定位工件。

Fixture and auxiliary support mechanism: the relative position of the workpiece can be fixed according to the machining surface or positioning hole of the workpiece. The movement of the fixture can be controlled manually, pneumatically, electrically and hydraulically to achieve clamping and positioning of the workpiece.

焊槍微調(diào)機(jī)構(gòu):要焊槍對(duì)準(zhǔn)焊縫,需要對(duì)焊槍的X\Y\Z向進(jìn)行三維調(diào)節(jié),是焊槍的指向?qū)?zhǔn)焊縫,同時(shí)根據(jù)焊接工藝要求,還需實(shí)現(xiàn)各方向的旋轉(zhuǎn)功能。

Fine adjustment mechanism of welding gun: to align the welding gun with the weld, three-dimensional adjustment of X Y Z direction of the welding gun is required, which is to align the welding gun with the weld. At the same time, according to the requirements of the welding process, rotation in all directions is also required.

焊接工件或焊槍的移動(dòng)機(jī)構(gòu):要完成直線、圓周或曲線焊縫的焊接,需要焊槍與工件的焊縫的軌跡的相對(duì)運(yùn)動(dòng)才能完成焊接要求。可以選擇焊槍移動(dòng),也可選擇工件運(yùn)動(dòng)。

Moving mechanism of welding workpiece or welding gun: to complete the welding of linear, circumferential or curve welds, the relative movement of the welding gun and the weld seam of the workpiece is required to complete the welding requirements. You can select the welding torch movement or the workpiece movement.

這個(gè)需要根據(jù)工件的形狀和尺寸來決定設(shè)計(jì)思路。其設(shè)計(jì)原則是機(jī)構(gòu)簡(jiǎn)單、控制簡(jiǎn)單、工人裝卸工件方便為主。環(huán)縫焊機(jī)是工件運(yùn)動(dòng),焊槍不動(dòng)。直縫焊機(jī)是工件不動(dòng),焊槍直線運(yùn)動(dòng)。

This needs to determine the design idea according to the shape and size of the workpiece. The design principle is simple mechanism, simple control and convenient loading and unloading of workpieces. Circumferential welding machine is characterized by workpiece movement and welding gun immobility. Straight seam welding machine means that the workpiece is not moved and the welding gun moves in a straight line.

焊接專機(jī)的機(jī)械系統(tǒng)的構(gòu)成思路就是以上內(nèi)容了,大家可以作為參考內(nèi)容使用,當(dāng)然您有什么需求或者什么問題要了解的,可以隨時(shí)來我們網(wǎng)站http://maxsenz.com進(jìn)行了解!

The composition of the mechanical system of the welding machine is the above content. You can use it as a reference. Of course, you can come to our website at any time if you have any needs or problems to understand http://maxsenz.com Get to know!

上一篇:每次使用自動(dòng)焊接設(shè)備焊接操作前的檢查

下一篇:延長(zhǎng)自動(dòng)化焊接設(shè)備使用壽命就要做好事項(xiàng)