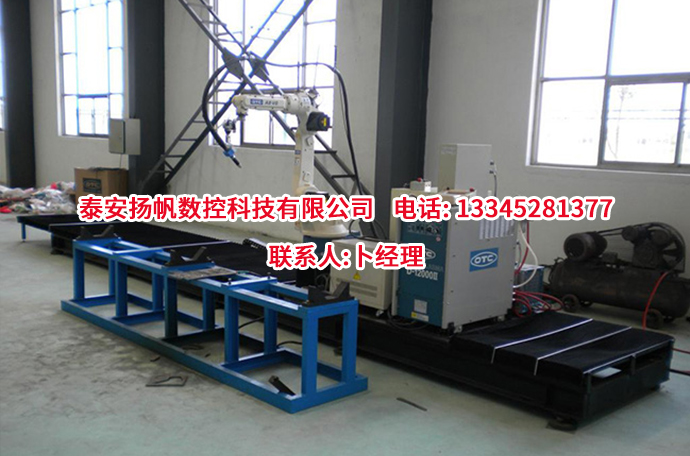

直縫自動(dòng)焊接設(shè)備的焊接方法

來(lái)源:http://maxsenz.com/ 發(fā)布時(shí)間:2022-09-14 瀏覽次數(shù):0

我們先要準(zhǔn)備好焊接的材料,檢查焊接材料是否平面整潔,如有污漬以及毛刺,要提前去清理掉,因?yàn)檫@些會(huì)影響焊接的效果。下面山東數(shù)控焊接設(shè)備廠家就來(lái)您講講相關(guān)內(nèi)容。

We should first prepare the welding materials and check whether the welding materials are neat. If there are stains and burrs, they should be removed in advance, because these will affect the welding effect. Next, Shandong CNC welding equipment manufacturers come to you to talk about relevant content.

1、打開(kāi)電源,調(diào)整好焊接的數(shù)據(jù),并輸入在觸摸屏系統(tǒng)里保存。

1. Turn on the power, adjust the welding data, and input it into the touch screen system for saving.

2、打開(kāi)焊機(jī)電源,并調(diào)整好,適合焊接此產(chǎn)品的電壓等參數(shù)。

2. Turn on the power supply of the welding machine and adjust the voltage and other parameters suitable for welding this product.

3、打開(kāi)氧氣瓶,并檢查氣體是否正常輸送。

3. Open the oxygen cylinder and check whether the gas is delivered normally.

接下來(lái)再和大家普及一下它的結(jié)構(gòu)特點(diǎn):

Next, let's popularize its structural features:

1、焊接電源。其輸出功率和焊接特性應(yīng)與擬用的焊接工藝方法相匹配,并裝有與主控制器相連接的接口。

1. Welding power source. Its output power and welding characteristics shall match the proposed welding process method and be equipped with an interface connected to the main controller.

2、送絲機(jī)及其控制與調(diào)速系統(tǒng)。對(duì)于送絲速度控制精度要求較高送絲機(jī),其控制電路應(yīng)加測(cè)速反饋。

2. Wire feeder and its control and speed regulation system. For wire feeder with high precision requirements for wire feeding speed control, its control circuit should be added with speed measurement feedback.

3、焊接機(jī)頭用其移動(dòng)機(jī)構(gòu)。其由焊接機(jī)頭,焊接機(jī)頭支承架,懸掛式拖板等組成,其驅(qū)動(dòng)系統(tǒng)應(yīng)采用裝有編碼器的伺服電動(dòng)機(jī)。

3. The welding head uses its moving mechanism. It is composed of welding head, welding head support frame, suspended carriage, etc. Its drive system shall adopt servo motor with encoder.

4、焊件移動(dòng)或變位機(jī)構(gòu)。如焊接滾輪架,頭尾架翻轉(zhuǎn)機(jī),回轉(zhuǎn)平臺(tái)和變位機(jī)等。

4. Weldment movement or displacement mechanism. Such as welding roller frame, head and tail frame turnover machine, rotary platform and positioner.

直縫自動(dòng)焊接設(shè)備的焊接方法就是這樣了,希望能夠給您好的幫助,當(dāng)然該設(shè)備也要定期進(jìn)行維護(hù)保養(yǎng),才能延長(zhǎng)它的使用壽命,更多注意事項(xiàng)就來(lái)我們網(wǎng)站http://maxsenz.com咨詢。

This is the welding method of straight seam automatic welding equipment. I hope I can help you. Of course, the equipment should also be maintained regularly to extend its service life. More precautions can be found on our website http://maxsenz.com consulting service

上一篇:數(shù)控焊接設(shè)備使用期常見(jiàn)到八種不好現(xiàn)象

下一篇:管法蘭自動(dòng)焊接機(jī)的主要優(yōu)點(diǎn)和維護(hù)修理